An item can be used in many skin care processes, like makeup removal, cleansing, toning …… Do you know what is it? Right! It is cotton pad.

We can see it on mall counters, online stores, supermarket shelves, downstairs stores ….. almost everywhere in our life. But materials and types of various cotton pads are totally different: non woven, degreasing cotton, spunbond, multi-layers, single-layers, crimped, or insertable design. The process required varies with the material and texture. How much do you know about the different types of cotton pads?

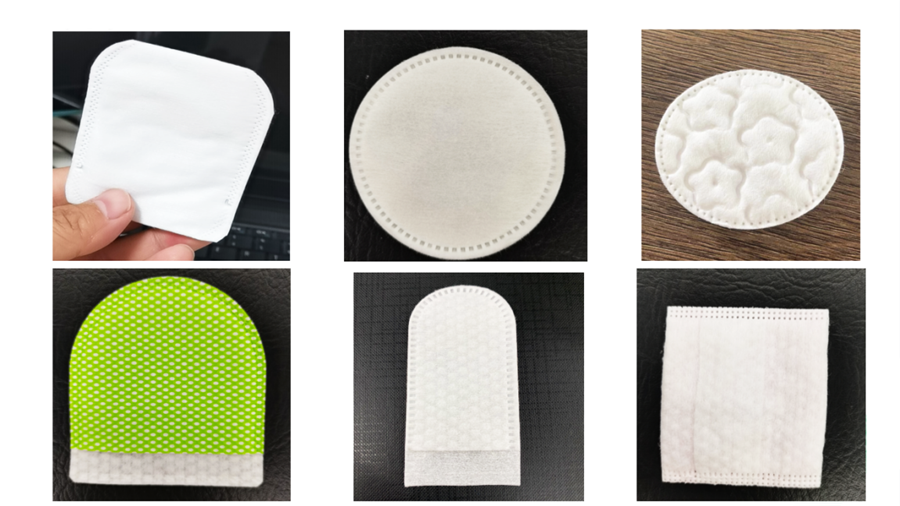

Shapes of cotton pads

There are several kinds of cotton pads:

1. Non-crimped cotton pads

This type of cotton pad is more absorbent, and the disadvantage is that it is too soft and easy to fall of the wadding. It can be used to remove eye makeup, and also be tron into several layers for wet compresses, saving both cotton pad and water.

2.Crimped and thickened cotton pads

It is not easy to fall off wadding because of crimping, so it can be used for removing makeup or secondary cleaning.

3.Insertable cotton pads

Insertable cotton pad is thicker, harder and tightly crimped. There is an opening on the back, easy to insert your fingers into, and can be used to remove makeup or for secondary cleaning. But It is not suitable for people with sensitive skin.

4.Thin cotton pad

This kind of cotton pad is also very water-saving, and will not fall off the wadding. But it is easily consumed and can be used for secondary cleaning, wet compresses or putting on the lotion. It can help to save skin care products and you will not be so heartbreaking.

5.Double-sided cotton pads

Some cotton pads are different on both sides,. One side is mesh and the other side is glossy. The glossy side is for hydrating and the mesh side is for cleansing, so it has multi functions and can be used for different purposes.

The production process of cotton pads

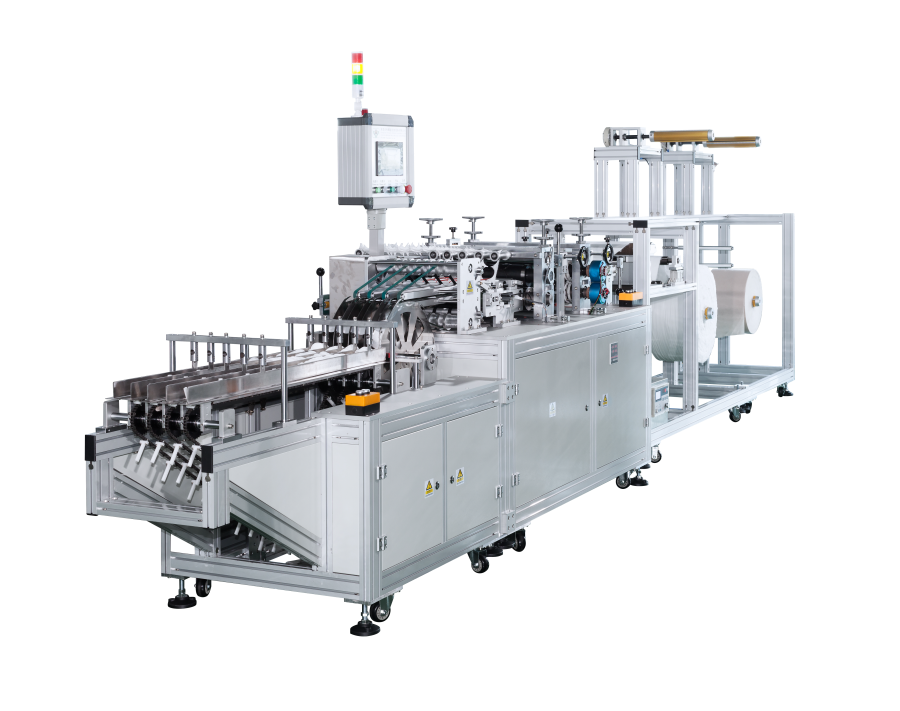

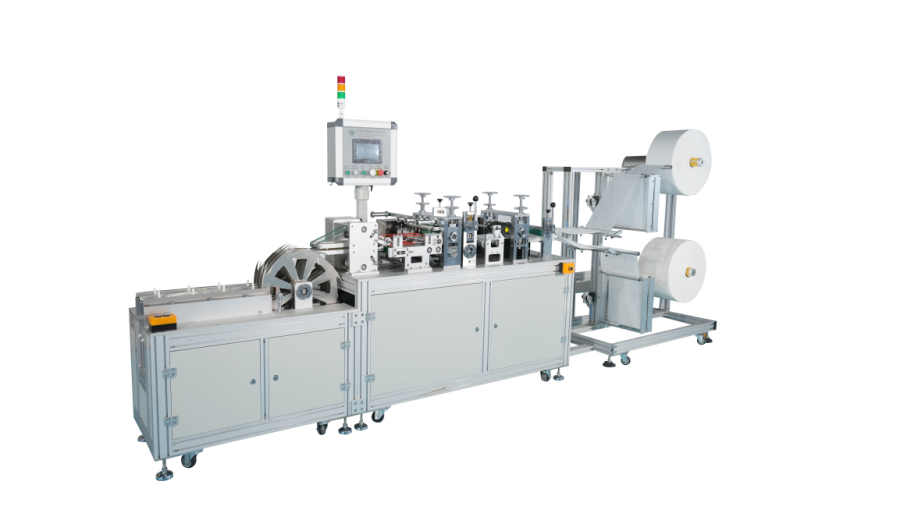

The general process of cotton pads making machine is as follows: loading raw material-automatic conveying – embossing- roll cutting – arranging and conveying the finished products – waste collection – automatic counting – the finished products. There will be slight differences in the process, but they are all pretty much the same.

The forming process of cotton pad is usually done by ultrasonic welding or heat melting technology to ensure that the whole production process can be completed at the same time from material feeding to finished products cutting and stacking. What’s more, unlike other processes, Hengyao cotton pads making machine can realized one machine for multiple uses. Just need to change different mould to produce different shapes and patterns of cotton pads. And it is not picky about the material in cutting, and the products cut out are without burr. The machine can collect the finished products neatly and has high efficiency.

(High speed cotton pads making machine- heat melt type)

(High speed cotton pads making machine- ultrasonic welding type)

Post time: Nov-18-2022