Slippers are essential in hotel room supplies. Some hotels initially provided recyclable plastic slippers, but the customer experience is generally poor, and if disinfection is not thorough, there will be health risks. As people’s consumption levels increase and they pay more attention to hygiene, disposable slippers have gradually gained popularity.

In order to cater to consumer needs and reduce unnecessary costs, many hotels have begun to provide disposable slippers. So do you know what specifications of disposable slippers are used in hotels of different grades?

Here, we briefly introduce the composition of hotel disposable slippers. It is mainly composed of soles, covers, sponges, uppers and edges. This article mainly distinguishes the differences between different grades of hotel slippers based on their structural differences.

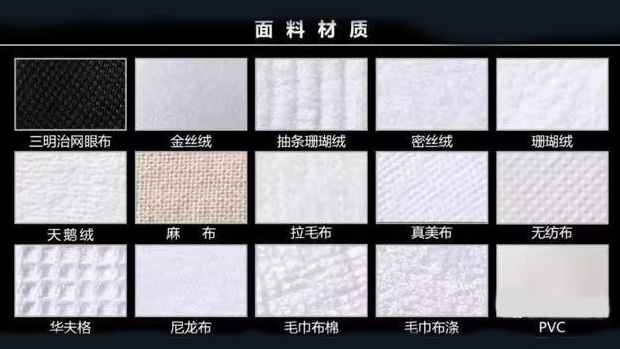

Fabric

There are many types of disposable slippers, mainly classified according to fabrics. The value from low to high is: non-woven fabric, velvet, brushed plush, short plush, towel, cut velvet, waffle, etc. As long as it is fabric, it can generally be used as the upper and cover of slippers, and usually they are made of the same material.

Generally speaking, small hotels and motels mostly use disposable non-woven slippers; mid-range hotels mostly use velvet, brushed plush, and short plush slippers; while high-end hotels prefer terry cloth slippers (terry, cut velvet). , waffle) and cotton/linen/ satin slippers.

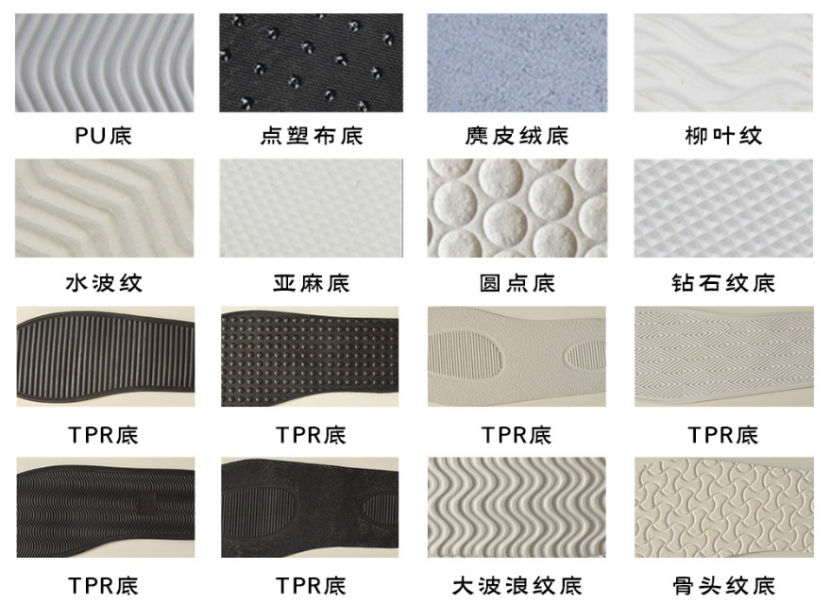

sole

The soles used in most hotels are still mainly EVA. Other materials include TPR soles, PVC soles, XPE soles, cloth soles, dot-plastic cloth soles, etc. The thickness of the soles is usually 4-7mm.

Regarding the choice of thickness, generally economical hotel soles will use thinner ones, around 3-5mm, while mid-range hotel soles will have a thickness of 5-6mm, and high-end hotel soles will have a thickness of over 7mm, with many being 8mm or 9mm. , the thickness is also directly proportional to the cost. If you want to increase the softness of the soles of your feet and improve the anti-slip properties, you can also add sponge to the soles of your feet.

Hemming

The hemming production techniques include one-handle wrapping, two-handle wrapping and three-handle wrapping. For one-handle wrapping, you cannot see the edge of the soles, but for two-handle wrapping and three-handle wrapping, you can see the material of the soles. The cost is as follows: one wrapping<two wrapping<three wrapping.

one wrapping craftsmanship

two wrapping craftsmanship

Automated production process of slippers of different grades

1. Disposable slippers manufacturing machine: Because the material of ordinary non-woven disposable slippers is relatively thin, it can be directly welded using ultrasonic waves. The welding is neat, beautiful and firm. Each process is fully automated and the product size and shape can be customized according to customer needs. It can be customized and can print personalized patterns, and can also be automatically connected to the packaging machine.

Disposable slippers making machine

Product display

2. Mid-end hotel slipper making machine: It can automatically weld the shoe upper after cutting it, and then use spray glue to composite each layer of materials. It can be used for the production of thick soles within 10mm. It has strong material compatibility and produces high-quality slippers. After simply changing the mold, children’s slippers can be produced.

Mid-end hotel slipper making machine

Product display

Luxury hotel slippers making machine: It uses ultrasonic welding and embossing after roll-cutting, pre-pressing and shaping the uppers. The texture is clear and beautiful. The soles are automatically glued and then compounded. The laser cutter is used to cut and shape the shoes in one go. The size is accurate and glued and sealed. Edge craftsmanship, natural fit, durable.

Luxury hotel slippers making machine

Product display

The automated production process is more efficient than traditional manual production, and the quality of slippers is more stable. But no matter what kind of slippers the hotel chooses to produce, when configuring slippers for guest rooms, it needs to combine the hotel’s positioning and style and configure slippers with appropriate quality, price, and style. Only in this way can it be recognized by consumers and achieve long-term development.

Post time: Oct-05-2023