Facial masks have become one of the most popular and commonly used cosmetic products. There are a variety of facial masks on the market, of which sheet masks, which consist of a facial mask base cloth and essence, are the most widely used. People mostly pay attention to the ingredients of the essence, but usually ignore the importance of the facial mask base cloth.

What is facial mask base cloth?

面膜基布,又称面膜布、面膜纸,是成分的载体,可以吸附精华液,固定在脸部特定位置,形成封闭层,减少水分的蒸发,促进精华液的吸收。

The facial mask base cloth, also known a the mask cloth or mask paper, is a carrier of the essence and is attached to the specific position on the face to form a closed layer to reduce the water evaporation and promote the absorption of the essence.

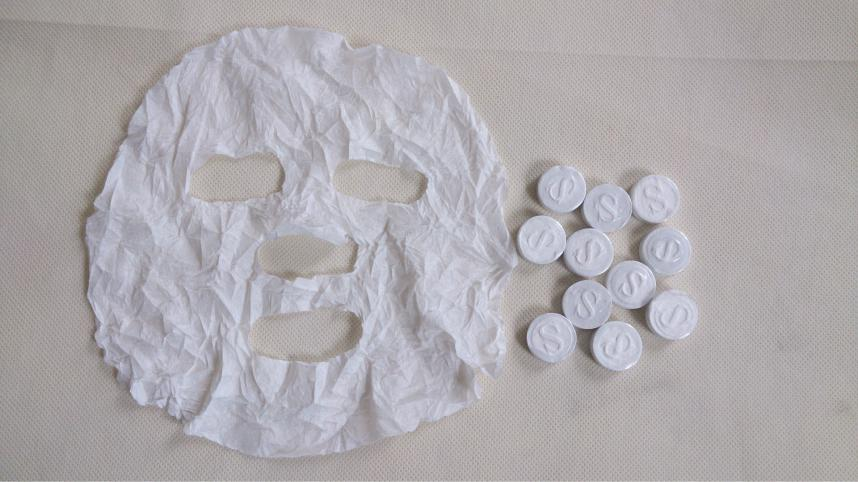

Mask paper are divided into compressed mask paper and non-compressed mask paper. The compressed mask paper is about the same size as a coin. It has 3mm thickness and is portable when travelling. Non-compressed mask paper has different thickness and size. Regular mask papers are used together with the essence made by our own.

Density, permeability and tensile strength of the mask fabric are the main factors influencing the absorption and skin contact. A good paper mask can help the essence to penetrate and be absorbed better, whereas a poor paper cloth not only affects the feeling of use, but also irritate the skin.

Common types and performance of mask cloth

Non Woven Mask Cloth: The most common mask cloth on the market is non woven, which is bonded directly to the fibers through physical methods.

Advantages: lightweight, soft, tactile, cost effective, stable performance, non-toxic and non-irritating;

Disadvantages: poor skin-friendliness, poor breathability, low liquid transfer rate, poor stretching stretchability.

Fruit Fibre Mask Cloth: The fruit fibre mask cloth is made by a special pressing process. The fruit fiber is extracted and separated from the plant using high technology.

Advantages: the cloth material is natural, skin-friendly, conforms to the skin and has a better moisturizing effect.

Disadvantages: The strength of the fruit fibre material is slightly poor, easy to loose deformation.

Silk Mask Cloth: The silk mask cloth on the market is divided into “real silk mask cloth”and “silk process mask cloth”. Most of the silk masks is made from natural plant fibre by organic solvent spinning process. It is very light and flattering, like the wings of silkworms, stretching like silk. Hence it is called as“silk mask”.

Advantages: It is lightweight, soft and silky, absorbent, breathable, absorbent and able to carry more essence.

Disadvantages: The essence on it evaporates easily. The real silk masks are expensive and do not stretch and break easily. Silk process masks vary in quality, so the manufacturer need to be carefully chosen.

Tencel Mask Cloth: It is a brand new fibre produced from natural tree fibre by solvent spinning method. It is softer and smoother than ordinary cotton fibre, natural and environmentally friendly.

Advantages: Absorbent, lightweight and skin-friendly, safe and environmentally friendly.

Disadvantages: the cost of the tencel mask cloth is high.

The production of mask cloth

The mask cloth supplied in the market is mainly non woven. Hengyao has developed 3D face mask sheet making machine, composite face mask sheet making machine, disposable compressed face mask making machine, facial mask sheet cutting and folding machine, face mask sheet making machine to help the manufacturers to produce mask cloth with high efficiency and low cost, and to meet different production needs.

(3D face mask sheet making machine)

(Composite face mask sheet making machine)

(Disposable compressed facial mask making machine)

(Face mask sheet cutting and folding machine)

Composite face mask sheet making machine can be compatible with the production of single-layer and double-layer material, and laminate an extra fabric on the forehead and cheek. The shape and size of face mask sheet can be customized according to customer’s needs.

3D face mask sheet making machine is cut into one piece by cutting roller to guarantee error-free product size. The use of industrial-grade hoovers to suck up the waste and the stacking mechanism at the same time saves the customer effort and energy.

Disposable compressed face mask making machine supports online humidification and can automatically regulate the humidity. It can produce different size by changing mold and can be used for muti purposes.

Face mask sheet cutting and folding machine is fully automatic from material feeding, cutting, folding and waste collection. It has a high and stable output of 130 pcs/min. The face mask sheet produced by the machine is perfectly folded.

In the future, face mask industry will maintain the trend of rapid development and fierce competition. Automated production is an effective way for manufacturing companies to improve competitiveness and strengthen market position.

Post time: Jun-26-2023