Six people are reported to have died in a biogas poisoning incident in Yongshan, Yuannan Province. This tragedy makes people feel very sad, but it has also made the public think about the poison gas problem. We all know that gas masks can effectively prevent gas or particulate poisoning, so how much do you know about gas masks?

Gas masks take a effective role in human protection.

A gas mask, also known as a gas respirator, is a personal labour protection item, as well as a individual protective item, worn on the head to protect the person’s respiratory organs, eyes and face from toxic substances such as poisonous gases, dust, bacteria, poisonous and hazardous gases or vapours, etc. It is extremely dangerous not to wear a gas mask or to wear a gas mask incorrectly. For example, workers who do not wear masks when grinding may suffer burns to the face and eyes; and prolonged work in high dust environments without masks can lead to poisoning or pneumoconiosis.

A gas mask mainly consists of filter element, mask body, transparent eyepieces, an exhalation valve and straps, etc. It is widely used in petroleum, chemical industry, mining, metallurgy, military, firefighting, rescue and disaster relief, health epidemic prevention and science and technology, environmental protection, machinery manufacturing and other fields. In addition, in cities with severe haze and photochemical smog, it plays an important role in personal respiratory system protection.

The classification of gas masks

Gas masks are divided into two types according to their protection principles: isolated gas masks and filtered gas masks. Isolated gas masks are protective devices in which the air (oxygen) required for the wearer’s breathing is not drawn directly from the air at the place of use, but is supplied by a separate air supply system. It is mainly used in workplaces where the concentration of hazardous substances in the air is high.

Filtered gas masks are designed to filter and purify the airborne contaminants to achieve the protection goal and are used in workplaces where the concentration of airborne contaminants is not high. They are generally subdivided into half face gas masks and full face gas masks. Half face masks are primarily designed to protect the human respiratory organs. Full face masks can protect not only the respiratory organs, but also the and facial skins. If the dust concentration in the workplace exceeds 10 times the occupational exposure limit, a full face mask should be selected.

Filters in the gas masks are the key to protection

The protective performance of gas mask is determined not by the mask body which merely insulates between inside and outside, but by the filter elements. The filter elements include anti gas box, anti canister, filter discs. It is the filter elements that make gas masks more protective.

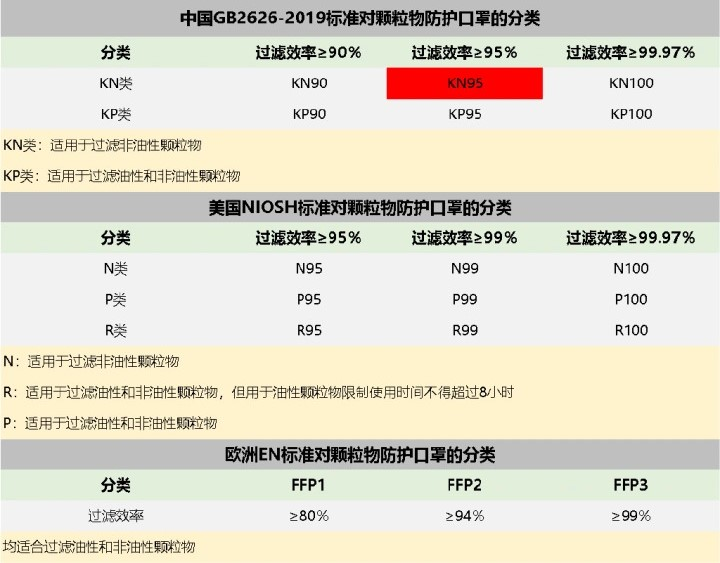

Filter cotton is the material used to filter dust and other substances in the air. It can be divided into non woven filter discs, synthetic fiber filter discs, glass fiber filter discs, activated carbon filter discs based on the different materials. According to Respiratory Protection Self-priming Filtering Anti-Particulate Respirator(GB2626-2019), Filter elements are classified into two categories, KN and KP, according to their filtering performance. The KN category is only suitable for filtering non-oily particles, and the KP category is suitable for filtering both oily and non-oily particles.

Over time, the filter cotton will become saturated, affecting its filtration performance, and must be replaced periodically. Depending on the material of the filter cotton and the actual working environment, the replacement time is generally 4-8 hours. At the same time, regular cleaning and disinfection of the mask is necessary to ensure its good condition.

The production process of filter discs is important.

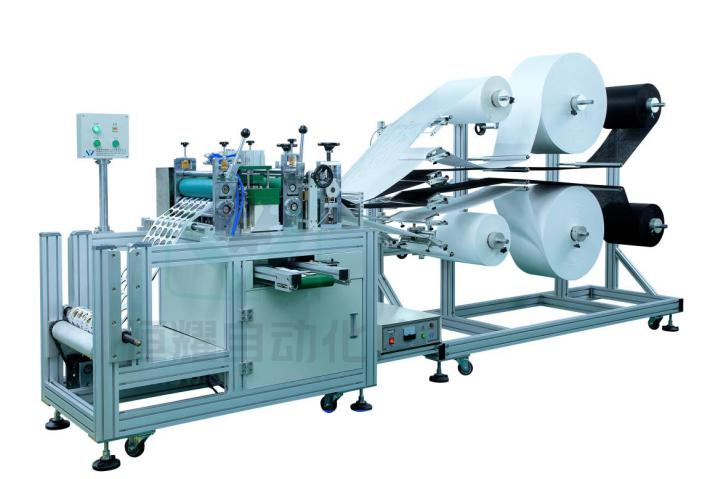

As the core component of gas masks, the production process of filter cotton is very important. Then how can we ensure the strictness of production and the consistency of product quality? This requires a fully automated production line, as it can effectively avoid excessive human intervention and pollution, thus improving production efficiency and stabilizing product quality.

HY Air filter discs machine is compatible with the production of many kinds of filter discs, and is convenient for changing mould. Meanwhile, by adopting frequency conversion motor control, the machine is easy to adjust the speed, allows continuous material movement, more stable welding and cutting, and guarantees product quality.

Air filter discs making machine

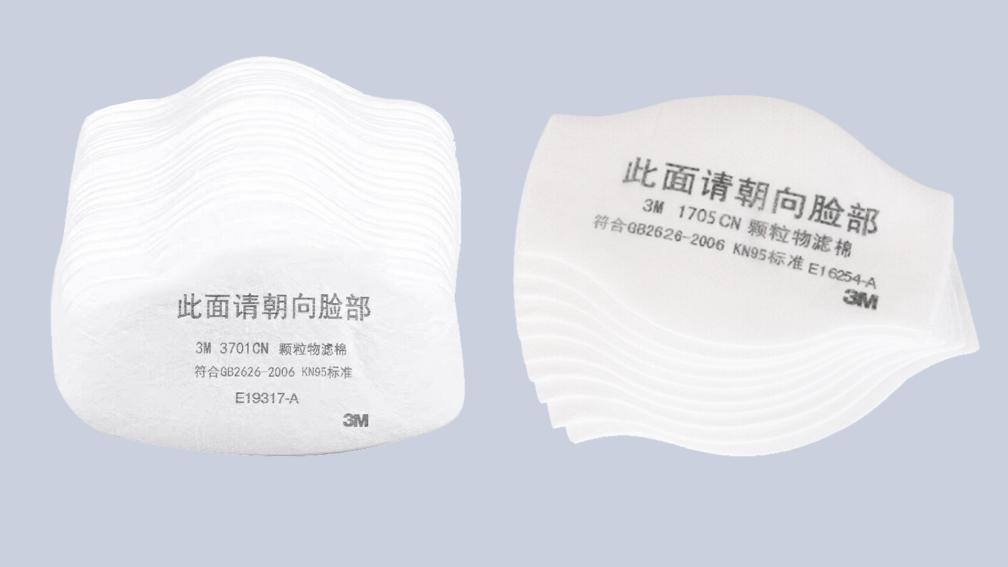

Product display

In order to adapt to different gas mask application scenarios, HY has developed a half face mask filter discs machine. It adopts ultrasonic imported ultrasound, which can weld 8 layers of materials at the same time including the attached activated carbon layer. In addition, the machine is equipped with automatic printing function so that the logo and pattern can be changed at any time. And the supporting skeleton of the filter discs can be customized according to the customer’s requirements.

Automatic respirator filter making machine

Product display

In addition, HY automatic respirator filter welding and cutting machine can produce different shapes of filter discs for the gas masks, and can change the materials and number of layers according to different mask bodies and application scenarios. The machine is equipped with automatic ink jet printing function and has a high degree of automation, which can reduce a large number of labour input.

Filter discs welding and cutting machine

Product display

Different types of gas masks can be used in different situations, so the manufacturing process and technology will also vary. However, regardless of the production process, the filter discs must pass through a strict production process and quality testing. Gas masks can provide a good filtering effect to protect the health of the human respiratory system.

Post time: Oct-04-2023