HY300U-04 New Energy Air Conditioner Filter Making Machine

- The fully automatic air conditioner filter manufacturing machine is an efficient and intelligent production line whose main function is to produce filters for air conditioners. The main features of the device are as follows: 1. High degree of automation: The equipment realizes fully automated production without manual intervention, which greatly improves production efficiency and production quality.

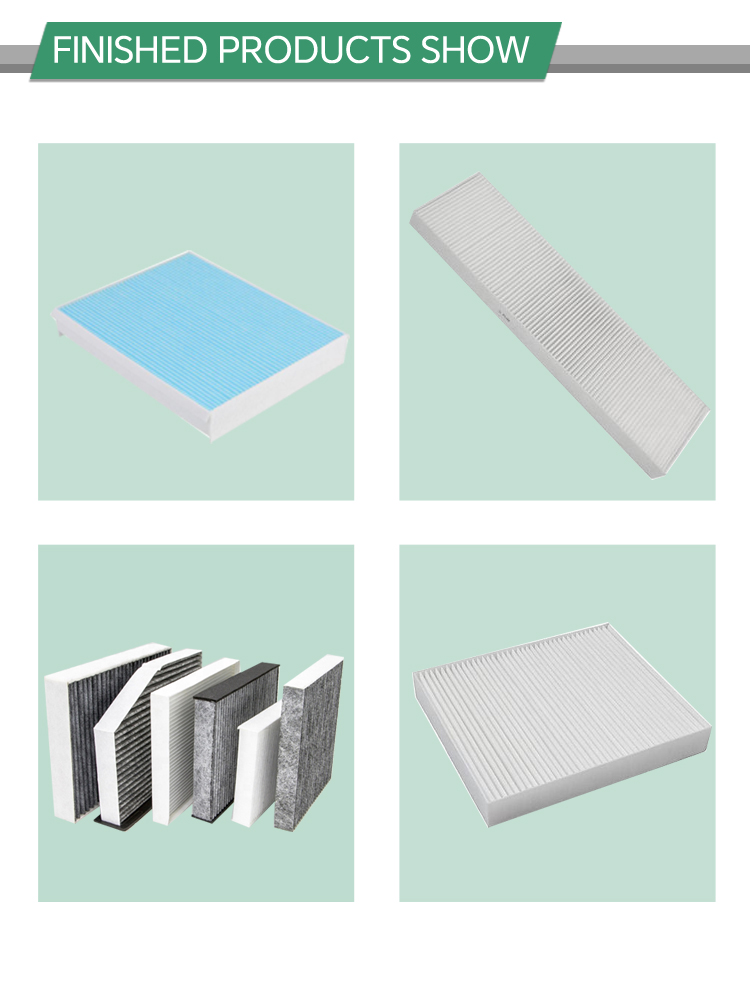

- Wide range of production specifications: The equipment can be produced according to different air conditioner models and different filter specifications, and the produced filters can meet various customer needs.

- 3. Easy to operate: The device adopts a touch screen operation interface, which is easy to operate and control, saving the operator's time and energy.

- 4. Good stability: The equipment is equipped with an advanced electrical control system and sophisticated sensors, which ensure the stability and accuracy of the equipment.

- 5. Automatic detection function: The equipment is equipped with automatic detection function, which can detect whether there are faults and abnormalities in the production process, and improve the reliability and stability of the equipment. 6. Quality control: The equipment adopts advanced production technology and production line, which can control the quality of each filter to ensure that each product meets the requirements.

- To sum up, the fully automatic air conditioner filter manufacturing machine is an efficient and intelligent production equipment, which can help enterprises improve production efficiency and production quality, reduce production costs, and is an indispensable and important equipment in modern production lines.

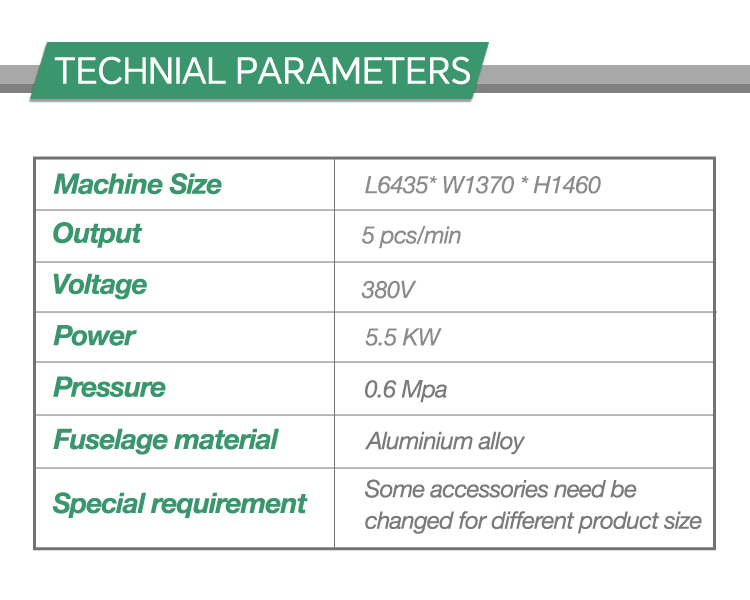

3.Machine Technology Parameter:

| Control Mode | PLC control |

| Machine Size | 6435*1370*1460MM |

| Capacity | 5 pcs/min |

| Voltage | 380V |

| Pressure | 0.6Mpa |

| Power | 5.5KW |

| Weight | 2300KG |

| Special requirement | Different size by changing mould |

- 4.Technical Features:

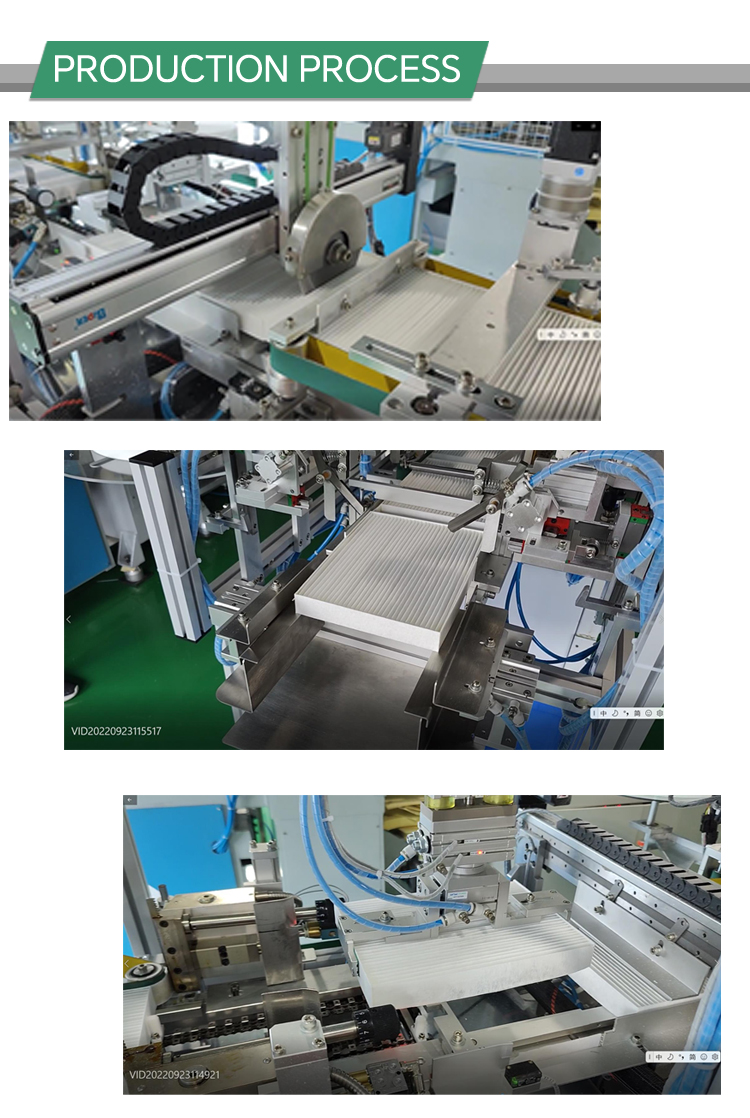

Through roller creasing and pleating, which make the machine be more stable and efficient

Use the impeller to control direction and stick the edge strip, which make distance evenly spaced.

Available for sticking the edge strips of four-side at the same time

5.Technology:

Rollers press crease and fold raw material → Access to impeller guidance → Apply hot melt glue to paste edge strip → Rotate cabin filter 90 degrees and apply another two edge strips → Cool and convey of finished products

Write your message here and send it to us