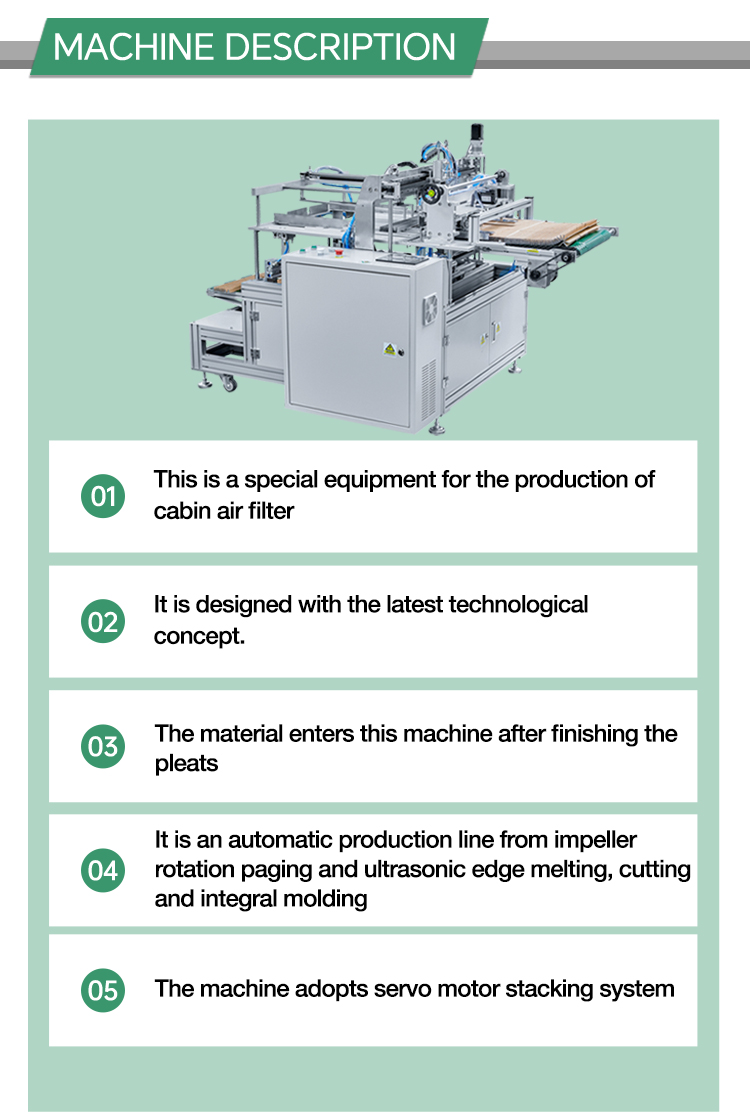

HY300U-05 Activated Carbon Melting and Cutting Machine

- Machine Description:

- Activated carbon melting cutting machine is an intelligent equipment, mainly used for hot-melt cutting processing of activated carbon sheets. Its main features are as follows:

- High-efficiency and energy-saving: the equipment adopts high-efficiency and energy-saving heaters, and has an automatic timing shutdown function to reduce energy consumption and improve production efficiency.

- High precision: the equipment adopts advanced hot-melt cutting technology, which can ensure the cutting precision is as high as 0.5mm.

- Easy to operate: it adopts touch screen control, which can realize fully automatic production, reduce the labor intensity of operators and improve production efficiency.

- Good stability: The equipment has high stability, and it is not easy to break down after long-term operation. It has automatic detection and fault alarm functions, which improves the reliability of the equipment.

- High safety: The equipment is equipped with multiple protection functions, such as overheat protection, overcurrent protection, water shortage protection, etc., to ensure the safety of operators.

- Easy maintenance: the equipment has a simple structure and is easy to maintain and maintain.

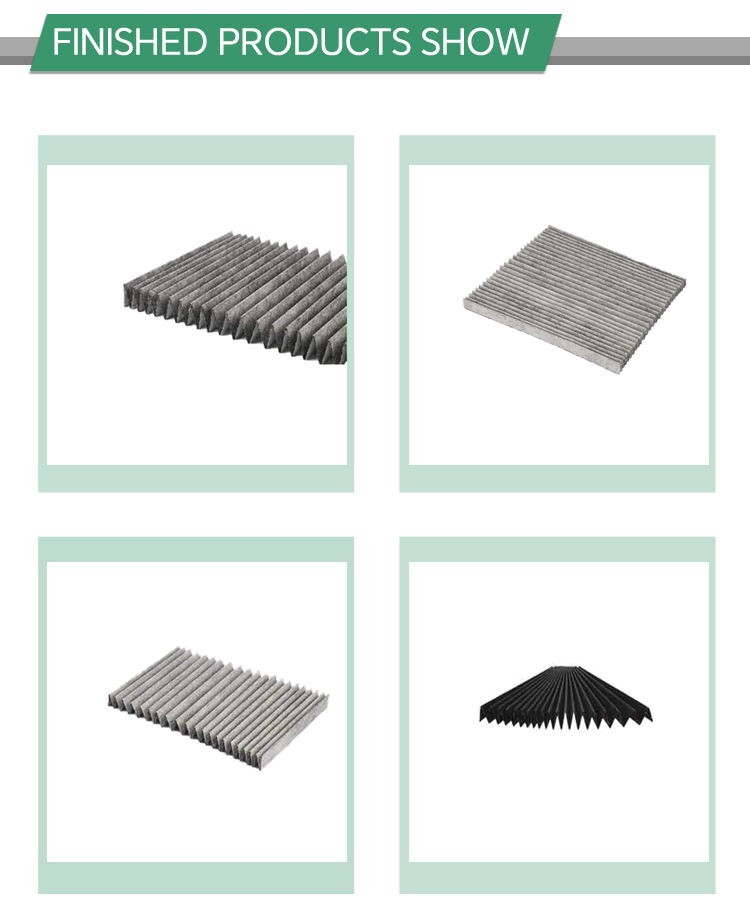

- To sum up, the activated carbon melting cutting machine is an efficient, accurate, easy-to-operate, easy-to-maintain, safe and reliable equipment, which is widely used in activated carbon filters, air filters and other fields, and can help enterprises improve production efficiency and reduce production costs , is an indispensable important equipment in modern production equipment.

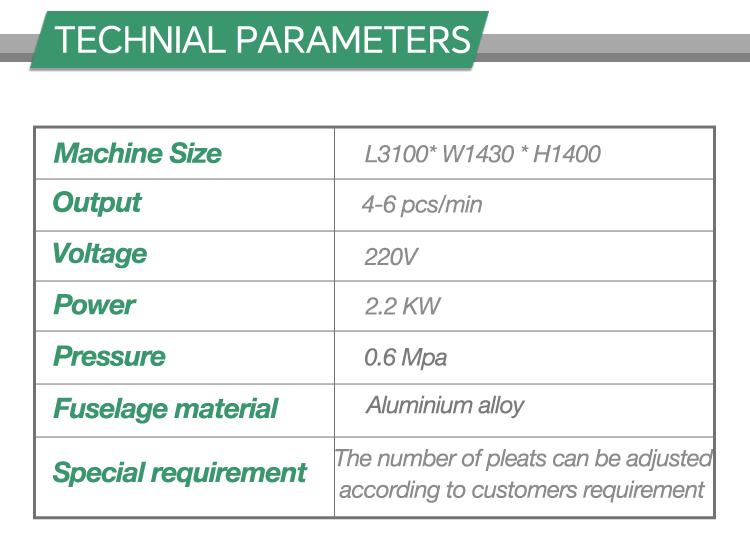

3.Machine Technology Parameter:

| Control Mode | PLC |

| Machine Size | L3100*W1430*H1400 |

| Capacity | 4-6pcs/min (23pleats) |

| Voltage | 220V |

| 气Pressure | 0.6Mpa |

| Power | 2.2KW |

| Weight | 420KG |

| Special requirement | The number of pleats can be adjusted according to customers requirement |

4.Technical Features:

Using servo motor to control the impeller, the number of pleats can be adjusted according to customers requirement

Using ultrasonic to welding while cutting at the same time, the finished product is neat

Connected with carbon filter pleating machine be full automatic production line

5.Technology:

The material completes the origami into the machine → Impeller rotation paging → Ultrasonic edge melting, cutting and integral molding → Servo motor stacking system

Write your message here and send it to us